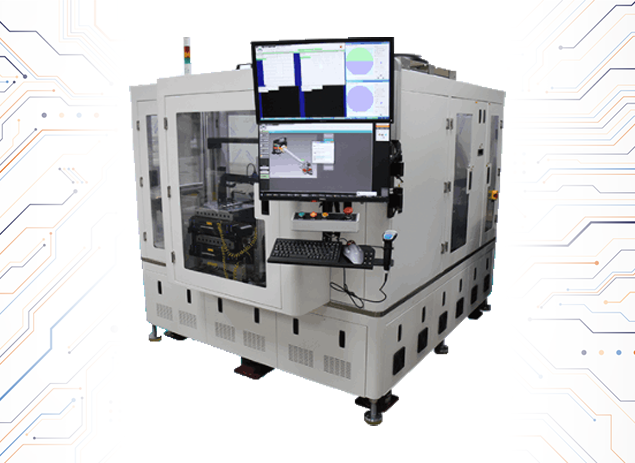

PM92 Tray-Level Laser Marking Handler

PM92 Tray-Level Laser Marking Handler A high speed tray to tray configuration laser marking handler designed for both semiconductors & MEMS components. It offers a

Home / Equipment / Semiconductor Machines And Manufacturing Equipment / Packaging and Assembly / Laser Marking

In today’s dynamic semiconductor environment, precision and speed are paramount. 4JMSolutions’ state-of-the-art laser marking machines deliver these crucial qualities, playing a pivotal role in wafer-level applications. Integrating advanced vision technology and a range of versatile lasers, these systems redefine efficiency and accuracy for today’s micro-electronic landscape.

Starting with the PM91 Strip-Level Laser Marking Handler Machine, this advanced system is designed explicitly for molded lead frames and substrates. Its unique ability to align a new mark to a device without surpassing a pre-existing mark, thanks to multiple megapixel cameras, ensures impeccable laser marking even on micro-sized devices. What’s even more impressive is its throughput, marking up to 800 strips for single-site and 400 strips for dual-site. Engineers and operators alike will also appreciate the variety in laser choices, ranging from YV04 to UV, making it suitable for marking various materials.

On the tray-level front, the PM92 raises the bar in laser marking wafer operations, catering specifically to semiconductors and MEMS components. With its capability to handle a staggering 6,000 UPH and an impressive assortment of compatible lasers, it maintains high-precision marking across a wide spectrum of packages. The laser marking silicon wafer system offers impeccable results due to its advanced vision technology that aligns and verifies markings.

The PM91-2D is another masterpiece for singulated modules/components. Its prowess lies in its high-speed marking ability, clocking a scan speed of 12,000 mm/s. With compatibility across multiple lasers like YV04, Fiber Green, or UV Laser, it offers versatility in marking applications.

The Trooper-L is built with an anti-vibration solid granite platform, it ensures flawless laser marking without the risk of misfires. Its specialty is laser marking silicon wafer with a precision of +/-30um. Its integrated Advanced Vision Systems ensure every wafer is aligned correctly before marking, and post-mark inspections validate the perfection of every marked wafer.

PM92 Tray-Level Laser Marking Handler A high speed tray to tray configuration laser marking handler designed for both semiconductors & MEMS components. It offers a

PM91-2D Singulated Module/Component Laser Marking Handler It is a fully automated high speed & precision laser marking handler designed for Singulated Module/Component. The handler comes

Trooper-L Wafer-Level Laser Marking Handler It is an innovative wafer-level laser marking handler which offers high precision laser marking capable of achieving an accuracy reading

PM91 Strip-Level Laser Marking Handler A high speed & precision automatic laser marking handler designed for molded lead frames or substrates The input can be

4JMSolutions understands the need to be always update and at the forefront of technology, this is why we select our world class suppliers with a

In the rapidly evolving world of electronics and manufacturing, precision dispensing equipment plays a pivotal role, ensuring accurate delivery of adhesive materials, especially when it

4JMSolutions offers a wide range Active Alignment Assembly which is designed to actively align & assemble together Collimator Module with DOE Module into a Projector,

4JMSolutions offers a wide range of Laser Cutting systems offering Half or Full cut to the highest of standards and quality, along with Laser Cutting

![]() 4JMSolutions (Malta) Ltd. was founded in 2008 on a solid base of international servicing and more than 25 years of high end industrial experience. Based on the solid principal of providing solutions where the equipment offered is a biproduct of the solution.

4JMSolutions (Malta) Ltd. was founded in 2008 on a solid base of international servicing and more than 25 years of high end industrial experience. Based on the solid principal of providing solutions where the equipment offered is a biproduct of the solution.