UV Cutting System

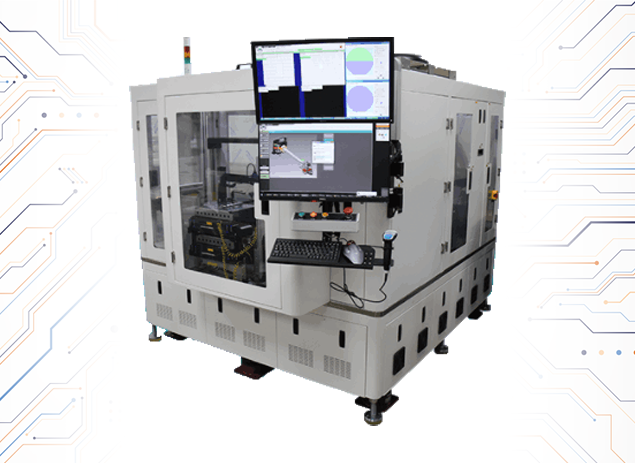

Eagle X5065C Laser Cutting System with UV Laser Apply : Pi Film, Coverlay, PCB, FPCB, RF-PCB, SLP, PPG, Cu Plate, Ag Plate, etc. Cutting Application

Home / Equipment / Semiconductor Machines And Manufacturing Equipment / Front-End / Laser App. Systems

Our Laser Application Systems for semiconductor manufacturing offer a range of wafer cutting and dicing solutions, including laser-based methods that provide precise and efficient processing. Our systems include the UV Cutting System, Trooper-L Wafer-Level Laser Marking Handler, Laser Repair Application, Laser Direct Patterning System with IR Laser, and CO2 Cutting System. All of these are designed to meet our customers’ needs.

At ![]() 4JMSolutions, we understand the intricate demands of semiconductor manufacturing, and it’s precisely why our advanced Laser Application Systems are tailor-made for the job. From intricate wafer cutting to precise laser dicing, our array of systems ensures not just efficiency but also unparalleled accuracy. The UV Cutting System, for instance, is ideal for a myriad of materials, including Pi Film and RF-PCB, boasting a superior cutting speed and impeccable accuracy.

4JMSolutions, we understand the intricate demands of semiconductor manufacturing, and it’s precisely why our advanced Laser Application Systems are tailor-made for the job. From intricate wafer cutting to precise laser dicing, our array of systems ensures not just efficiency but also unparalleled accuracy. The UV Cutting System, for instance, is ideal for a myriad of materials, including Pi Film and RF-PCB, boasting a superior cutting speed and impeccable accuracy.

On the other hand, the Trooper-L Wafer-Level Laser Marking Handler is a testament to innovation, bringing high precision laser marking on a Solid Granite Platform, ensuring precision and stability in every mark. Our Laser Repair Application – Eagle X7120RE uses the precision of IR wavelength to seamlessly repair and open short parts in ag paste, while the Laser Direct Patterning System with IR Laser – Eagle X7150H excels in fine pitch patterning, catering to diverse materials like Silver Paste and Transparent Electrode.

Lastly, for those seeking optimal laser cutting with a broader wavelength spectrum, our CO2 Cutting System – Eagle X5200G promises to deliver. All these systems embody our commitment to our clients, and at ![]() 4JMSolutions, we don’t just provide machinery; we offer holistic solutions ensuring our customers always have the edge in semiconductor manufacturing.

4JMSolutions, we don’t just provide machinery; we offer holistic solutions ensuring our customers always have the edge in semiconductor manufacturing.

1) UV Cutting System

The UV Cutting System is an advanced laser cutting machine that offers precise and efficient cutting for a wide range of materials, including Pi Film, Coverlay, PCB, FPCB, RF-PCB, SLP, PPG, Cu Plate, Ag Plate, and more. With a UV laser and cutting application by UV wavelength, the system provides exceptional accuracy, with cutting speeds of up to 3,000mm/sec and cutting accuracy of ±10μm(average). One of the key advantages of the UV Cutting System is its ability to provide high-quality cutting for even the most complex shapes and patterns, thanks to its 2D On The Fly + Step Cutting capability. It also features a large work field of 650 * 650 (mm), with the option for user-defined fields and a beam spot size control of up to 25μm. Additionally, the system is equipped with Laser Power Auto Offset, which ensures consistent cutting quality and minimizes the need for manual adjustments. As a wafer dicing machine, the UV Cutting System is ideal for semiconductor manufacturing companies looking for an advanced and efficient solution for wafer cutting and dicing. Its high speed, accuracy, and versatility make it suitable for various applications, including RF, FPCB, PCB, SLP, Coverlay, Pi Film, and more. With its advanced UV laser cutting technology and user-friendly interface, the UV Cutting System is a powerful tool for optimizing production processes and improving yields.

2) Trooper-L Wafer-Level Laser Marking Handler

Introducing our latest innovation in wafer-level laser marking: a high-precision handler built to mark wafers with unmatched accuracy and dependability. Our wafer-level laser marking handler is an industry-leading solution that guarantees accuracy and consistency in each mark with a +/-30um accuracy reading. Our wafer-level laser marking handler is constructed with a solid granite platform and anti-vibration absorbers to give a stable, aligned base that prevents laser misfire. It provides automated vision-guided wafer positioning for maximum accuracy and ensures it is correctly aligned before being marked using cutting-edge vision technology. This handler can mark up to 1.8 frames per hour and handle wafer cassettes of different widths, ranging from 6 to 12 inches. The vision system makes wafer alignment in the X-Y and angle possible, enabling accurate and reliable marking. The operator can take pictures and keep track of the entire marking procedure while viewing a live feed, giving real-time feedback on the marking procedure. Our wafer-level laser marking handler is available with a green or UV laser per your needs. Additionally, following marking, our vision system does a post-mark assessment to ensure the results adhere to the exacting standards established by our customers.

3) Laser Repair Application

The Laser Repair Application is a specialized machine designed to open the short part of each channel in Ag paste using the laser. It operates on IR wavelength and has a maximum beam spot size control of 15μm or less. With a maximum repair speed of 3,000mm/sec, it can repair circuits quickly and accurately. The work table size is 70 inches and can be customized according to user specifications. This machine is ideal for repairing circuits in semiconductor devices, including those used to produce silicon wafers. Its precision and speed make it an essential tool for high-tech manufacturing industries.

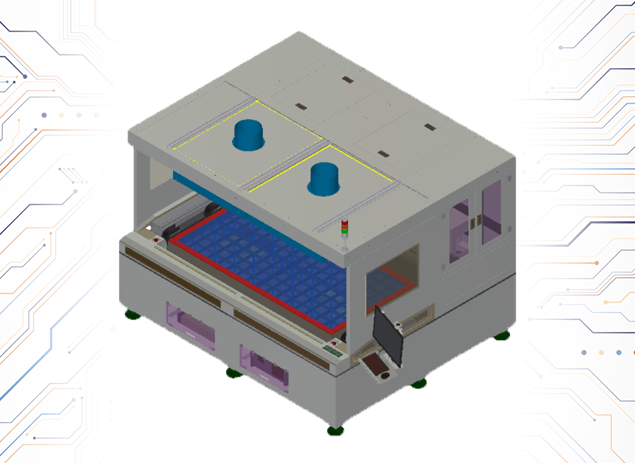

4) Laser Direct Patterning System with IR Laser

The Laser Direct Patterning System with IR Laser is a state-of-the-art machine designed for fine pitch patterning using laser and scan head. This equipment is suitable for applying the silver paste and transparent electrodes such as ITO, Ag Nano Wire, and CNB, among others. With a line width control of a minimum of 15μm and a line stitch accuracy of a minimum of ±3μm, this machine can achieve precise patterning at high speeds of up to 5,000mm/Sec. The scanning field is user-defined, and the work table size is 70 inches, customizable per the user’s requirements. The Laser Direct Patterning System with IR Laser also features a multi-head option. This machine is ideal for various industries, including wafer dicing, laser cutting, and silicon wafer cutting.

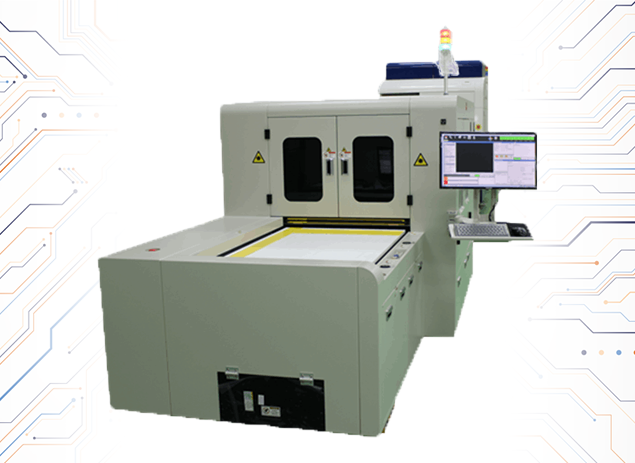

5) CO2 Cutting System

The CO2 Cutting System is a powerful laser cutting machine that operates on the CO2 wavelength. It is designed to easily cut through films, making it an ideal choice for many industrial applications. Its advanced beam spot size control can achieve a maximum spot size of 100μm, allowing for precise and accurate cuts. This machine also features a maximum cutting speed of 500mm/sec, ensuring it can quickly and efficiently handle even the most demanding cutting jobs. The work field is 2,000 x 1,000 (mm) but can also be customized to meet the specific needs of each user. This makes it a versatile and reliable choice for industries looking for high-quality laser cutting solutions.

Eagle X5065C Laser Cutting System with UV Laser Apply : Pi Film, Coverlay, PCB, FPCB, RF-PCB, SLP, PPG, Cu Plate, Ag Plate, etc. Cutting Application

Trooper-L Wafer-Level Laser Marking Handler It is an innovative wafer-level laser marking handler which offers high precision laser marking capable of achieving an accuracy reading

Eagle X7120RE Laser Repair Application Repairing Application by IR Wavelength Equipment to open the short part of each channel in ag paste using laser Beam

Eagle X7150H Laser Direct Patterning System with IR Laser Fine Pitch patterning using Laser and Scan Head Apply : Silver Paste and Transparent Electrode (ITO,

Eagle X5200G Laser Cutting Application Cutting Application by CO2 Wavelength Film Cutting Beam Spot Size Control : Max 100㎛ ~ Max. Cutting Speed : Max

The Vanguard of Flip Chip Bonding Technology The transformative wave of miniaturization and enhanced connectivity in the semiconductor world is largely driven by pioneering technologies

4JMSolutions – Pioneering Excellence with Advanced Die Bonder Machines Die bonding, often regarded as the heartbeat of the semiconductor assembly process, finds its true innovation

Die Sorter Machines 4JMSolutions takes pride in its lineup of state-of-the-art Die Sorter Machines, which come fully integrated with AOI (Automated Optical Inspection) systems. Die

4JMSolutions is proud to offer advanced wafer Automatic Optical Inspection (AOI) systems from leading manufacturers. These systems play a crucial role in the semiconductor manufacturing

The Trooper-BI Wafer-Level VCSEL/LED/Micro LED Burn-in wafer level testing system is highly versatile and can accommodate a wide range of units, up to 7,200 at

Our Laser Application Systems for semiconductor manufacturing offer a range of wafer cutting and dicing solutions, including laser-based methods that provide precise and efficient processing.

![]() 4JMSolutions (Malta) Ltd. was founded in 2008 on a solid base of international servicing and more than 25 years of high end industrial experience. Based on the solid principal of providing solutions where the equipment offered is a biproduct of the solution.

4JMSolutions (Malta) Ltd. was founded in 2008 on a solid base of international servicing and more than 25 years of high end industrial experience. Based on the solid principal of providing solutions where the equipment offered is a biproduct of the solution.