JAP-3000 Automatic Pick & Place System for Pre-Inspected Wafer

JAP-3000 Pick & Place System for pre-inspected wafer Automatic Pick & Place System for pre-inspected wafer Wafer to Tray process Easy to apply various DDI

Home / Equipment / Semiconductor Machines And Manufacturing Equipment / Test and Finishing / AOI for Semiconductors

![]() 4JMSolutions is revolutionizing this sector with a range of sophisticated automated optical inspection machines tailored specifically for wafers, dies, and encapsulated semiconductors. Here are some of our AOI Machines:

4JMSolutions is revolutionizing this sector with a range of sophisticated automated optical inspection machines tailored specifically for wafers, dies, and encapsulated semiconductors. Here are some of our AOI Machines:

The Eagle V8500 Machine, a 3.5D vision inspection system, which stands as a testament to Korea’s cutting-edge technology, being the first to introduce the Slit Beam Method for PKG inspection. Not only does it boast high precision warpage inspection, but it’s also designed for efficient automation, enhancing productivity without compromising on accuracy.

The Eagle V8000 Machine. A pioneering system that integrates APS + AVI, it offers multiple vision perspectives, ensuring comprehensive inspection from wafer inception to the waffle tray. Emphasizing user efficiency, its modes range from fully automatic to dry run, catering to diverse operational needs.

The JAI-3000 Machine integrates both 2D and 3D vision systems, specifically tailored for package visual and marking inspections for TSOP and BGA types. It ensures only the best devices proceed after stringent 2D/3D and marking inspections.

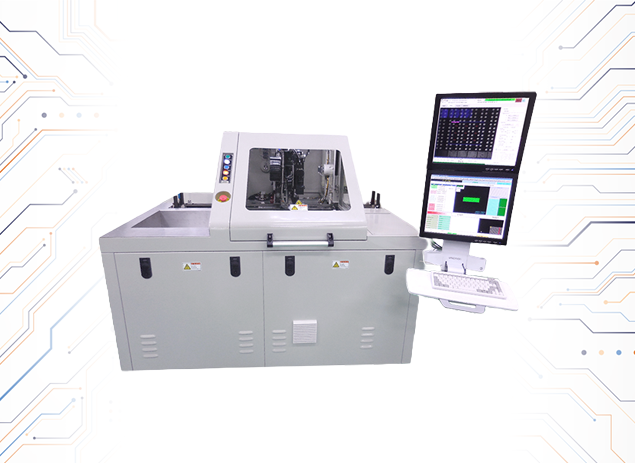

Designed for pre-inspected wafers, the JAP-3000 excels in accuracy, boasting a positioning precision of 0.01mm. Its dual vision system ensures flawless chip placement, adapting seamlessly to various DDI configurations.

The Trooper-V Wafer-Level AOI Handler. A high-speed marvel, it can inspect a staggering 70,000 dies in a mere 120 seconds. With its advanced microscope, high-quality objective lens, and diverse vision capabilities, Trooper-V is an embodiment of next-generation AOI testing.

JAP-3000 Pick & Place System for pre-inspected wafer Automatic Pick & Place System for pre-inspected wafer Wafer to Tray process Easy to apply various DDI

JAP-3100 Pick & Place System with Vision inspection Automatic Pick & Place System with Vision inspection Wafer handling by magazine : Auto Wafer Loading &

JAI-3000 2D / 3D Auto Vision System with 20 para tool for package visual and marking of TSOP, BGA Types Vision Inspection Stations : 4

JAI-2000 2D / 3D Auto Vision System for package visual and marking of TSOP, BGA Types The Devices in the Loading Tray are inspected by

Eagle V8000 DDI Chip Auto Pick & Place and Vision Inspection Inline World first APS + AVI combination system Wafer Vision, Under Vision, Top Vision,

JAI-D302 Chip handled on Waffle Pack, Vision Check, Sorting, Unloading Reduced equipment operation time by Loader / Un-loader system Waffle Pack Warpage correction function Easily

Eagle V8500 3.5D vision inspection equipment Slit Beam Method : first PKG inspection application in Korea Ball Apex (3D Data) detection function using Slit Beam

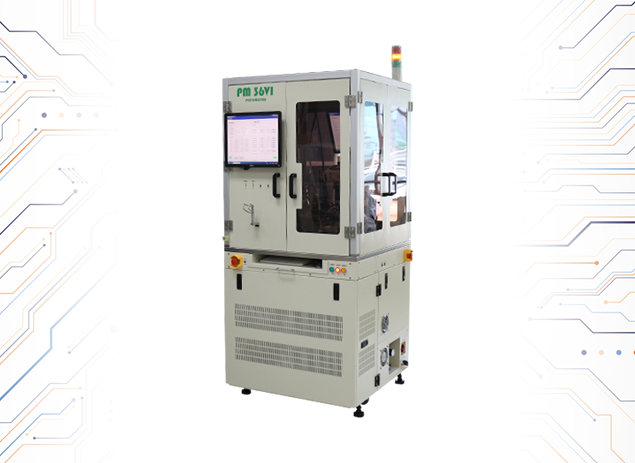

PM52-V Final AOI Packaging Handler PM52-V is a linear based concept mass production handler designed to perform final inspections onto IGBT before packing them into

Trooper-V Wafer-Level AOI Handler for Semiconductors Trooper-V is next level high speed AOI handler designed for wafer-level packages. In just 2 minutes, trooper v inspection

PM42-RT Reel to Reel Vision Inspection Handler It offers the solution to fully automate Post Seal Vision Inspection of Reel to Reel output. The handler

PM36 / PM36XL Glass Turret Base Vision Inspection Handler It is a high speed vision sorting handler designed to handle passive components such as transistor,

PM35-V Turret Base Vision Inspection Handler A high speed turret base vision handier designed for both Leaded and Leadless packages. The handler is equipped with

MV-6E OMNI Series The optimal 3D AOI to improve productivity The world’s best performance 3D AOI Non-blind spot digital 8 projection moiré 3D inspection technology

MV-3 Series Versatile off-line 2D AOI Great inspection performance Inspection for diffuse reflection component, OCR, micro crack precisely by 8 phases coaxial color lighting Angled

![]() 4JMSolutions (Malta) Ltd. was founded in 2008 on a solid base of international servicing and more than 25 years of high end industrial experience. Based on the solid principal of providing solutions where the equipment offered is a biproduct of the solution.

4JMSolutions (Malta) Ltd. was founded in 2008 on a solid base of international servicing and more than 25 years of high end industrial experience. Based on the solid principal of providing solutions where the equipment offered is a biproduct of the solution.